It is critically important to understand the best way to handle and store down. Too much humidity during storage of the bulk material can accelerate the growth of mold and cause significant and sometimes irreparable damage. Additionally, down needs to breath so we bag in breathable bags. This necessitates storage off the floor in order to keep it both clean and protected from foreign elements that could eventually find their way into the filled products.

- allied feather + down

One of the best attributes of down is its durability and longevity. In a world of fast fashion, your down jacket is one item in your closet that can last a lifetime. All that is needed is proper care – of which the information around down care can be misleading at best and destructive at worst.

It is a lot easier to care for your down product than many people think. All it takes is the proper detergent and a little patience. Clean down is able to retain more warmth, has better loft, better compression, will look and feel better, and leads a longer functioning life cycle of the product. Taking proper care and regularly cleaning your down will keep it performing as well as – if not better than – the day you bought it.

Washing down is not unlike washing our hair.

The down cluster itself is a Beta Keratin protein, and as such, much of the same care is needed with down as we take with that hair on our head. Too much oil or dirt or any other foreign substance, and it goes flat and clumpy. Soap or chemicals that are too harsh can strip it of the oils we need for it to be bouncy and resilient, making it brittle.

And like our hair, the down cluster contains essential fats and oils that are necessary to retain resiliency and loft. When we process material at ALLIED, we look to retain a very precise amount of these, while achieving an extremely clean product. This is why the composition of the detergent itself is extremely important. Harsh chemicals and overprocessing can cause irreparable damage.

Think of our ALLIED DOWN WASH as a shampoo for your down jacket.

One of the best attributes of down is its durability and longevity.

Additives like bleach or other harsh chemicals in most laundry detergents might be able to get your product clean quickly, but can strip the down of those fats and oils necessary for the performance and durability of the product.

You would never use your hand soap for your hair, so why would you use a regular detergent for your down?

It is actually quite easy to clean your down product.

The two biggest things you can do to damage the down inside a garment is to use harsh detergents, and to not dry completely. While we always suggest following the recommended washing instructions on the garment, the following is generally the best way to wash your down product.

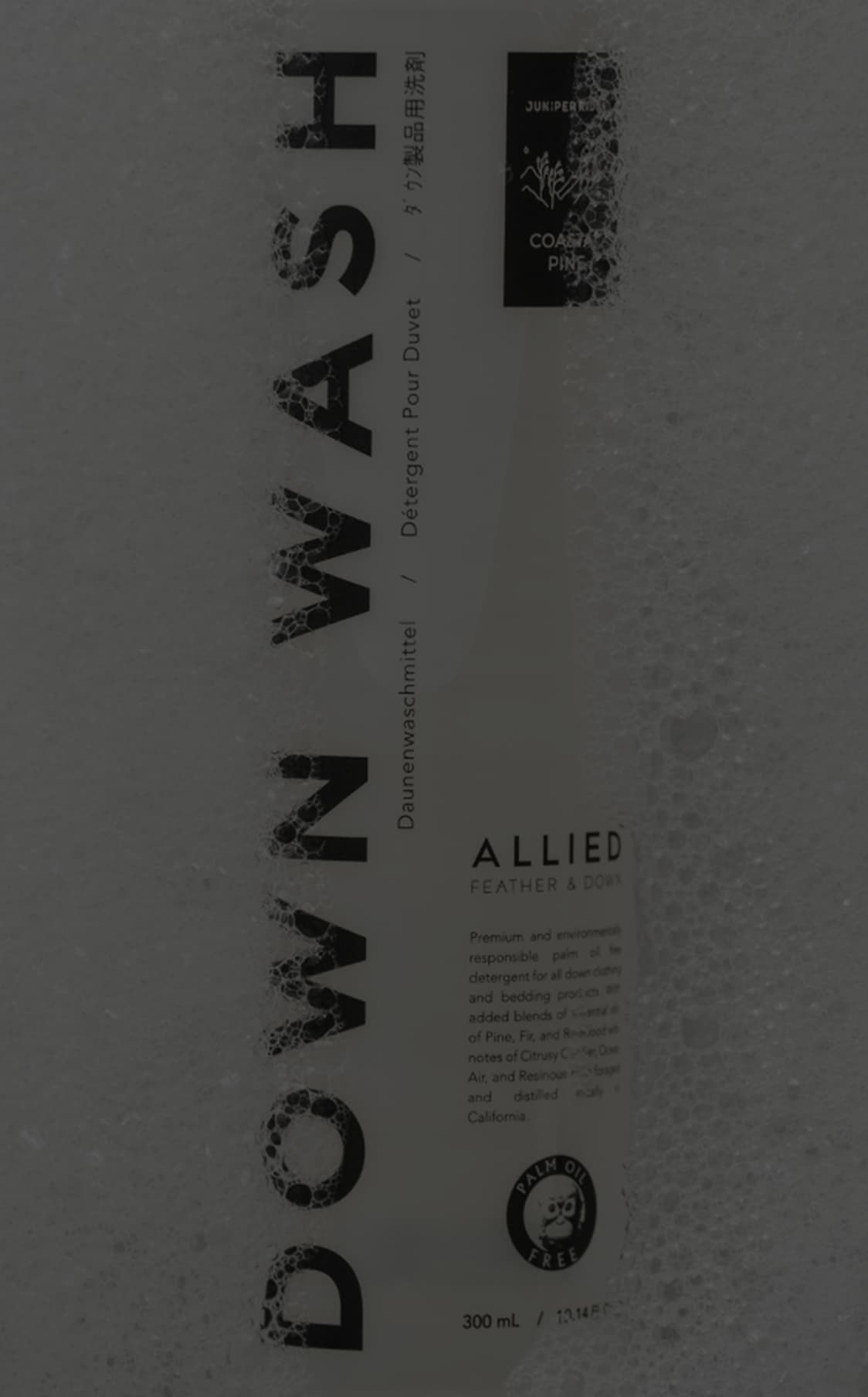

It is critical to start with a detergent specifically created for down products, like our ALLIED DOWN WASH.

| step 1 PRE-RINSE |

If possible, pre-rinse products without detergent. This helps to saturate the items allowing the detergent to penetrate the fabrics more effectively and get to the down clusters to clean them thoroughly. |

| step 2 LOW TEMP WASH |

Wash on low temperature. There is a greater likelihood that the fabrics will require a lower temperature than the down itself. This also saves energy when it is not needed. |

| step 3 ADDITIONAL RINSE |

Following wash, run an additional rinse without detergent. This will ensure that all detergent was completely rinsed out of the down and the product. Leaving residual detergent on the down may cause a reduction in fill power. |

| step 4 TUMBLE DRY |

Tumble dry on low temperature until completely dry with clean tennis balls or a clean shoe. |

If you think the item is dry, it is worth running one last dry cycle. Many people assume it is dry by the feel of the textile, but the down inside remains slightly damp. This may take several cycles. It is not possible to over-dry in a home laundry machine, and is always better to err on the side of dry with down insulation.

It may be obvious, but do not bleach or iron your down filled products.

We also generally recommend against dry cleaning, but if that is necessary because of certain trims on the item, it is recommended to use an eco-friendly dry cleaner who has experience with down filled products.

After 30 years of processing some of the highest performing and cleanest down in the world, we have worked with our bluesign® system chemical partner to develop a home laundry detergent to get the down inside your products as clean as the day it left our facilities. And we have done all this without using palm oil derivatives and with detergents that are completely safe for the environment. When you are using the world’s most eco-friendly insulation, equal care should be taken with the products used to clean it.

There are other “down washes” on the market, and we have found that most of them do a good job at cleaning the garment and protecting the down. They do this by using very little active ingredient to keep from stripping the fats and oils. These all come from chemical companies that may understand the chemistry behind cleaning fabrics, but don’t have the experience and knowledge of cleaning down that we do. Down, as a natural material, can quickly grow mold, bacteria and other allergens if not properly cleaned. It can also be stripped of its natural resiliency and insulating characteristics if cleaned too harshly. It was our goal to create the best detergent for the cleaning of the down itself. This required a lot of work to reformulate our renowned production detergent for home use. The goal was to create a detergent with a high concentration of an active ingredient that attacked the dirt, mold and grime down can collect after use. If you purchase a down-specific detergent, you expect it to actually clean the down, not just the face fabric.

We have also worked with our friends at Juniper Ridge, who have foraged and locally distilled an essential oil from our California backyard to provide a slight scent that reminds you of waking up in a forest near the ocean’s edge. The ingredients are responsibly foraged and hand distilled here in California.