It is important to start with the knowledge that almost all down sold to the apparel and bedding industries is a by-product of the food industry. It is estimated that down only accounts for 2-8% the total value of the bird. No birds are being raised solely for their down.

If everyone stopped buying down products, it would have no effect on the amount of birds being raised.

There are, however, significant concerns within the supply chain and ALLIED does everything we can to make sure all of our sources are using best practices for all animal husbandry. And if there are changes that can be made, we actively assist in making those knowing that at 2-8%, there is little incentive for these farmers and abattoirs to implement changes themselves.

The two most important issues we face is the sourcing of down coming from birds that have been force fed for Foie Gras or live plucked.

Force feeding

In parts of the world, farmers engage in a practice of force feeding duck and goose to enlarge their livers for the foie gras industry. Since a large majority of duck in Europe are raised for foie gras, this issue probably represents the biggest volume potential.

For years, ALLIED has rarely sourced any duck down from Europe for this reason. It is a relatively cheap and easy implementation for farms to switch production and there are issues within countries where this is legal for farms to engage in parallel production. The risk is high in these regions so we have chosen to source around the issue.

Live plucking

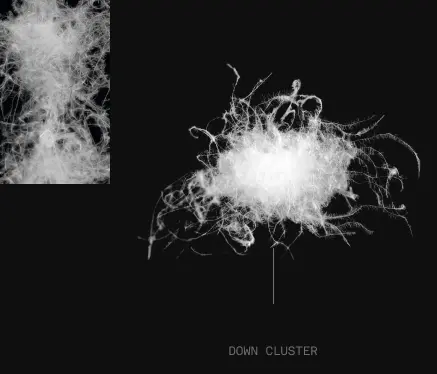

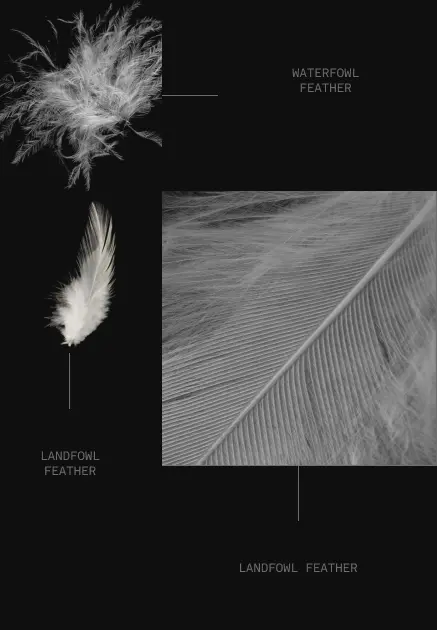

Live plucking is an abhorrent practice where older birds that would molt naturally have their down systematically ripped from their chests. While this practice is arguably the more sinister of the issues, it is also a very small percentage of the global supply at risk for this treatment – regardless of the misinformation perpetuated by the animal welfare groups.

Live plucking occurs where birds live long enough to seasonally remove the down. These birds will regrow the the down and thus remain at risk for further plucking the following season. The only place this can occur is within the parent farms where birds can live several years for the sole purpose of laying the eggs that go to market and raising farms for production of meat. In the industrial supply chain, birds go to the abattoir at between 8-11 weeks so there is no possibility of this practice to occur outside of these parent farms.

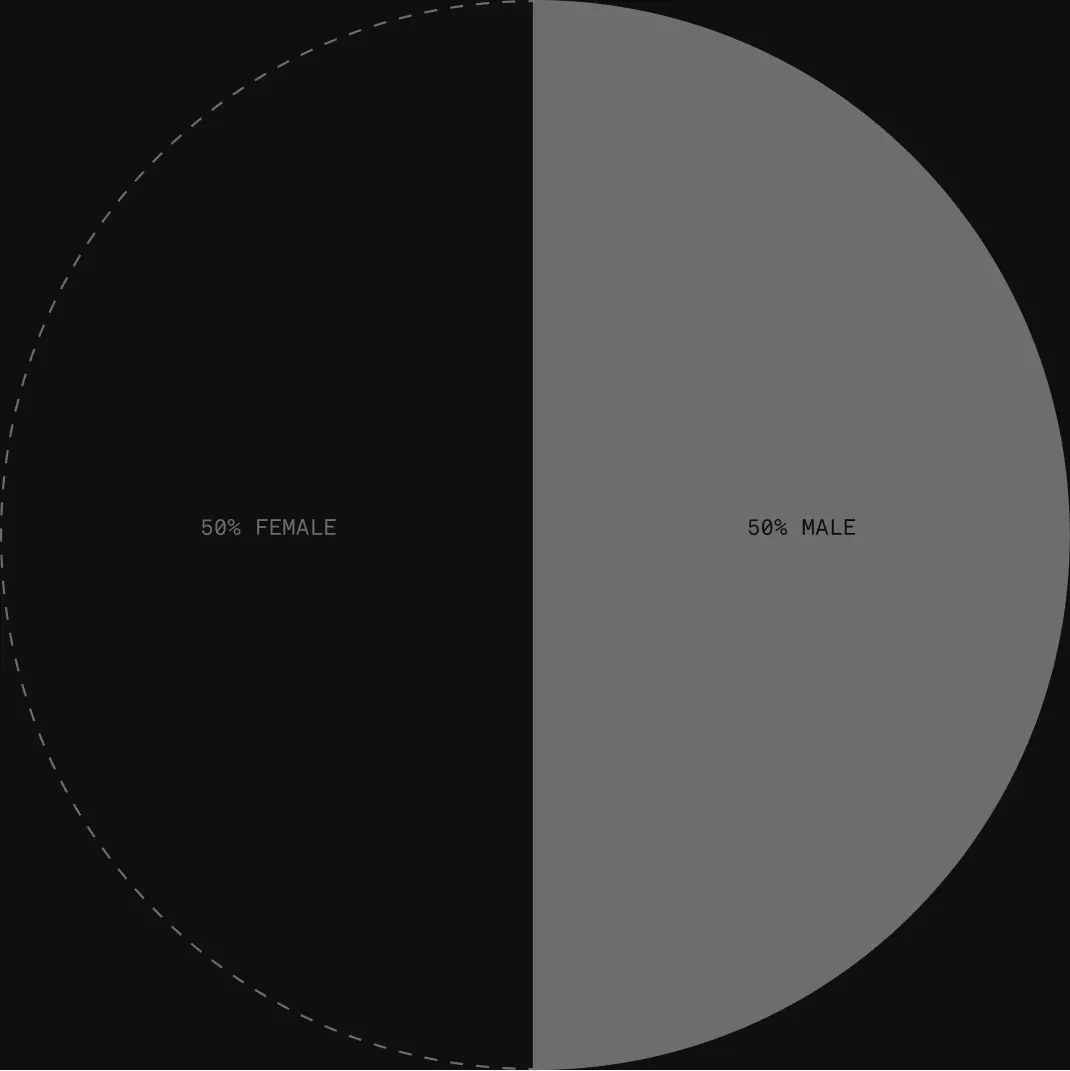

This practice can also only occur with White Geese. Other species can not handle this treatment and will die. And since the bird is far more valuable as a parent goose, killing the bird this way is counter productive. The practice also only applies to the industrial supply chain which accounts for only 50% of the global supply. The remaining 50% comes from a rural small farm supply chain where there is generally very little to no animal welfare risk at all.