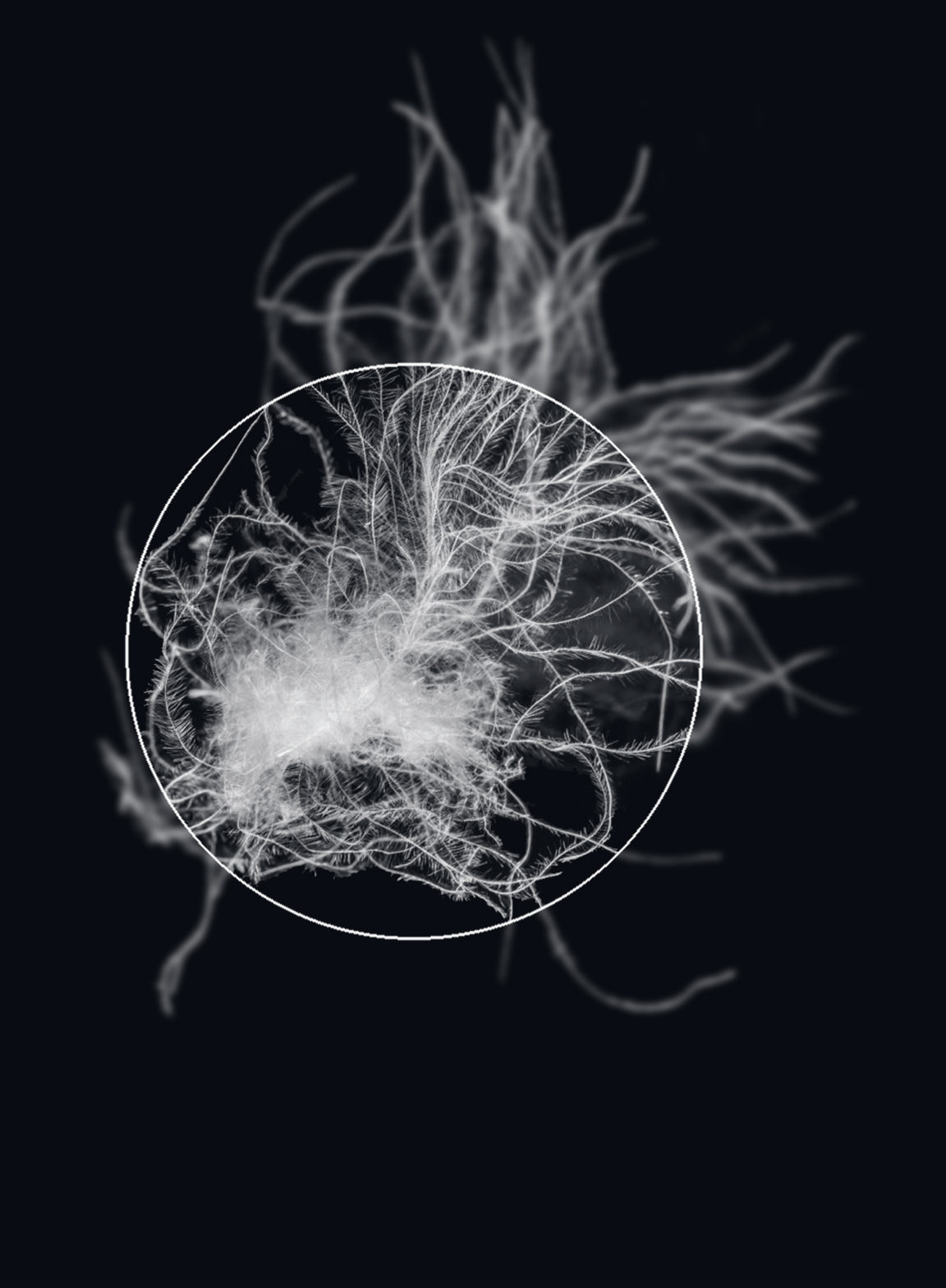

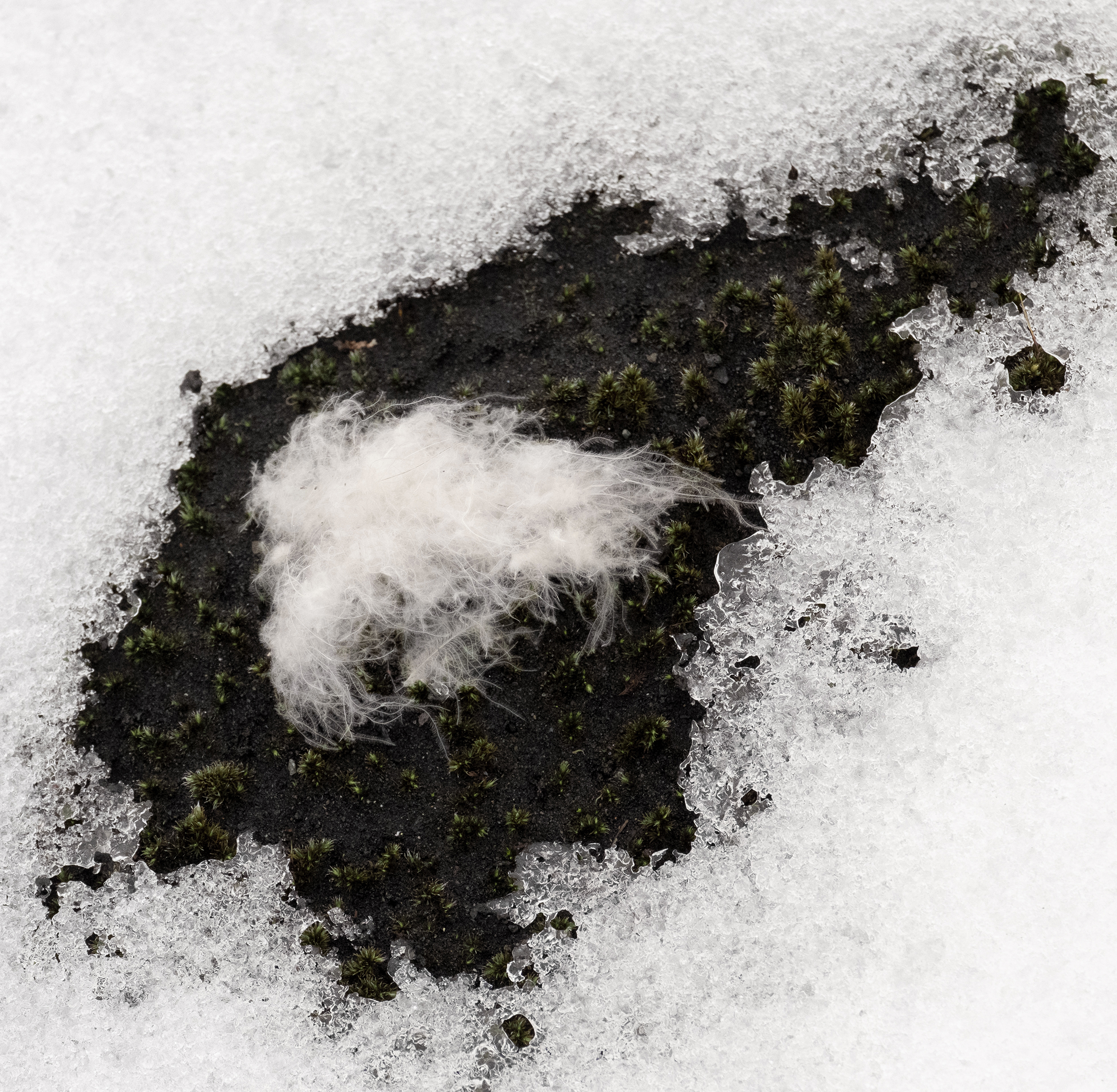

The natural brilliance of the down cluster is that it is able to fill a volume with very little material and incredibly low weight.

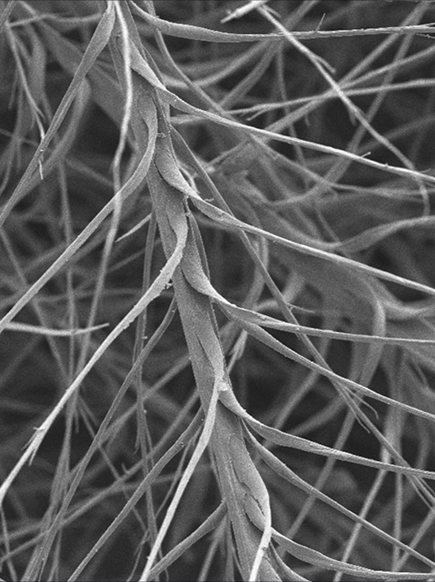

Each filament is just a fraction of the width of a human hair, and it is estimated that there are as many as 30 miles of these filaments in just one gram of down.

While widely misunderstood, there are small differences between the down clusters of the duck and goose. The goose down cluster tends to have longer filaments, a different barb shape and a unique fat and oil composition. This all makes the larger goose down cluster slightly more compressible and resilient when it comes to jackets or sleeping bags that need to provide as much warmth as possible with minimal weight. Both insulate in the same way and more often than not it is almost impossible to distinguish between the two.

The down cluster is composed of a protein — beta keratin — which is very similar to our human hair.

Like our hair, it has fat and oils that give it bounce and resiliency. But again like our hair, proper processing, care and handling are needed to ensure durability, which can long outlive any garment.